Extrusion blow molding Find suppliers, processes & material

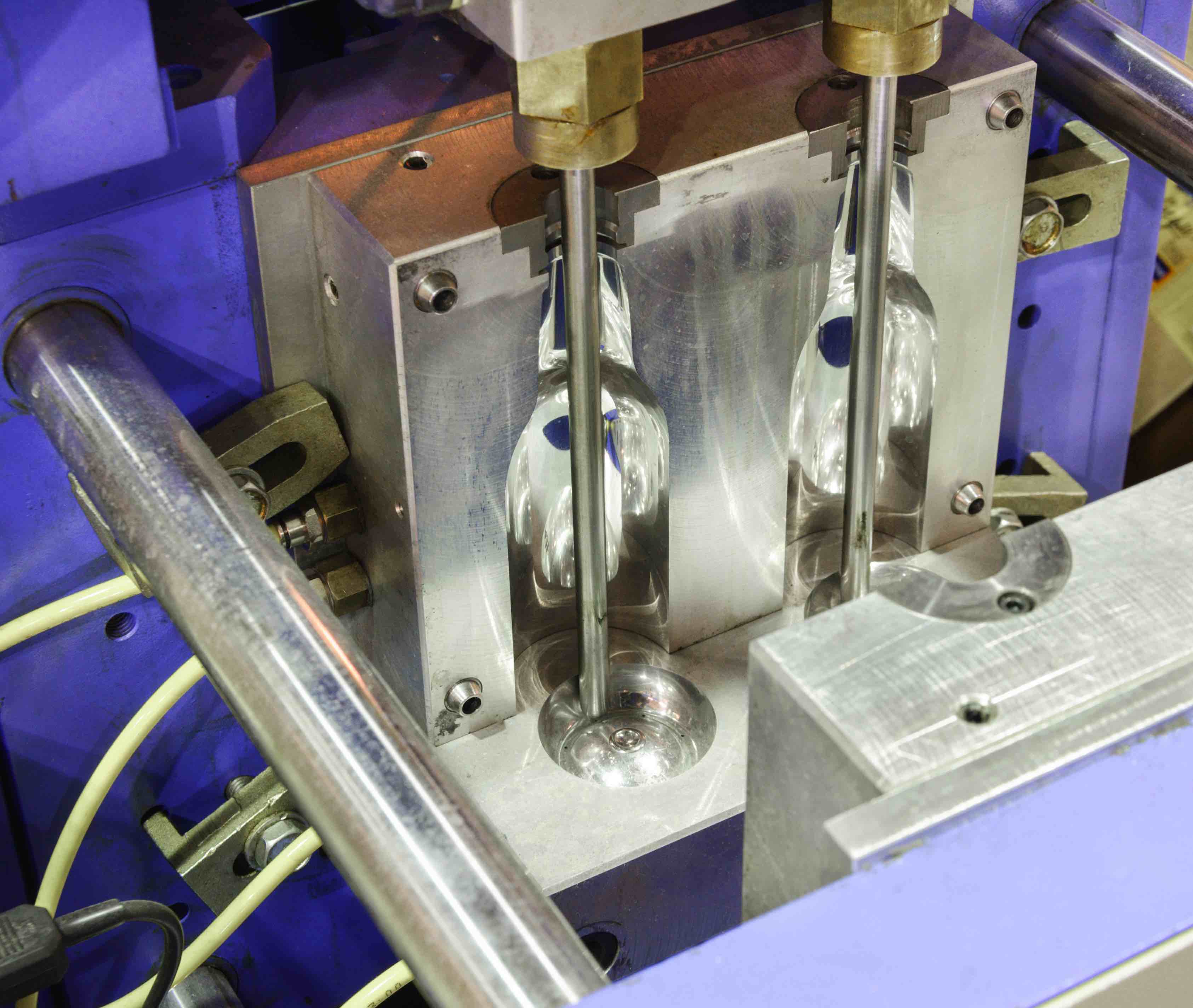

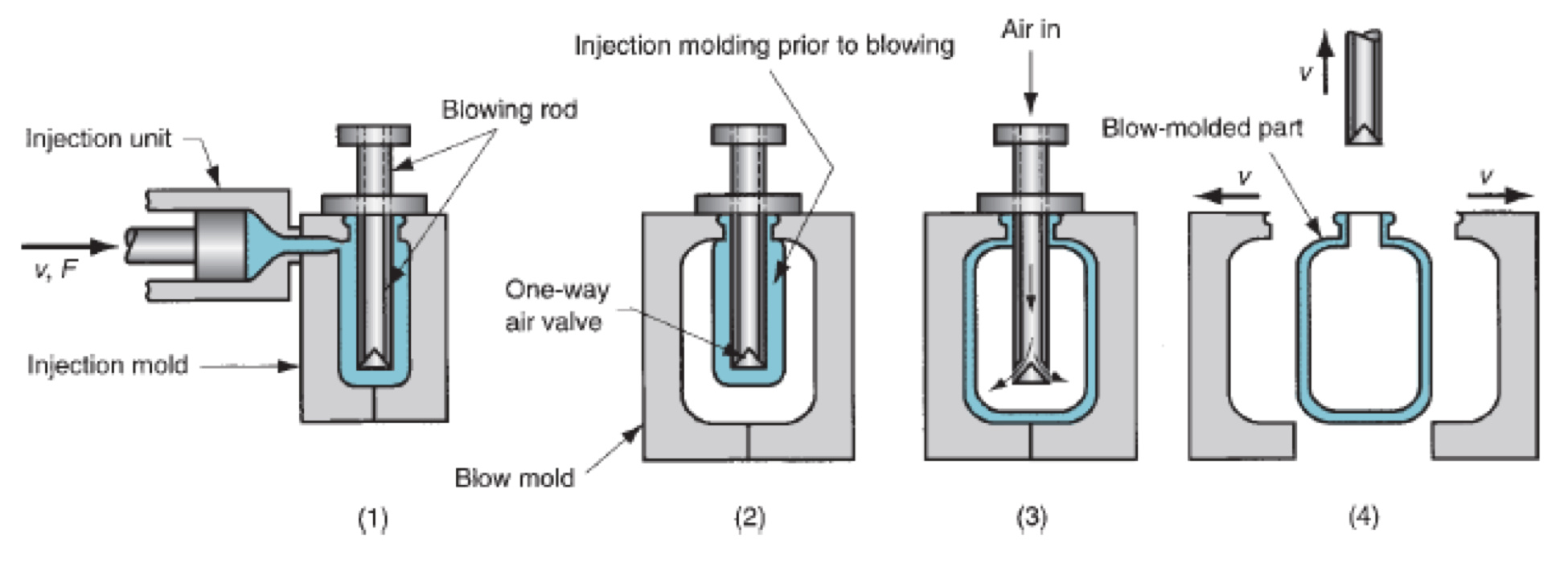

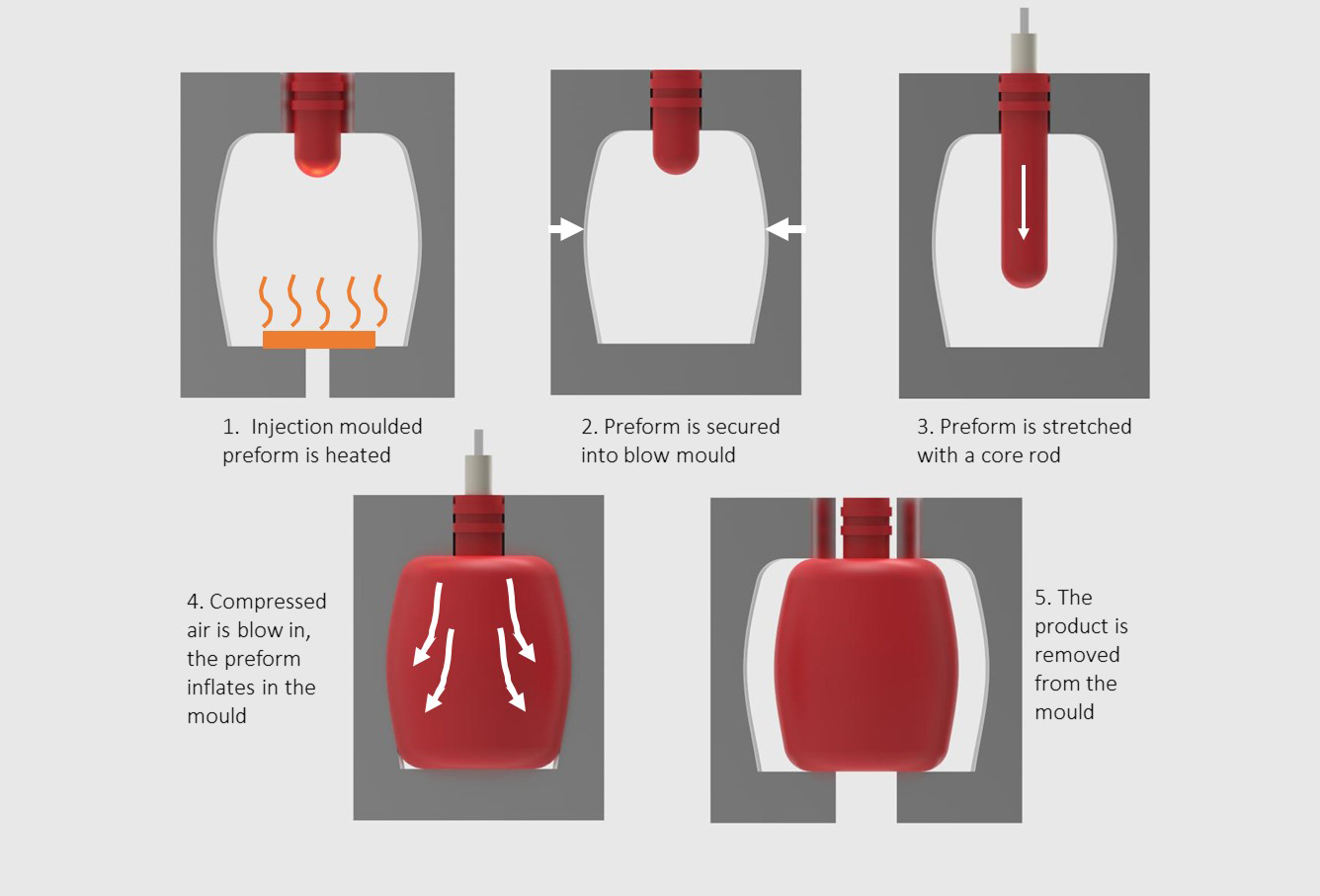

Blow molding is a plastic-forming technique used to create hollow plastic items out of thermoplastics. This method involves shaping the intended product by inflating a heated plastic tube, known as a parison or preform, inside a mold. By injecting air, the tube expands, providing thin walls that cling to the mold’s shape.. Researchers examine impact of single-use vs. reusable takeout containers. Jim Johnson. Senior Reporter. Reprints. University of Michigan, Live Zero Waste. Reusable containers filled with takeout.

Best Machines to Make Blow Molding Products

MGS250L Extrusion Blow Moulding Machine MEGA

Basics of Blow Molding Consumer Hardware Guide Hardware FYI

Best Extrusion Blow Molding Monroe Mold Blow molding, Mould design

Blow Mold Replacement Light Cord Christmas Lights Creations

Custom Blow Molding Currier Plastics

Extrusion blow molding Find suppliers, processes & material

What Type of Products Are Produced with Blow Molding? SEALECT

Plastic Molding Service for Medical Industry Blow Molded Containers

What is blow mold ? Torchmold

Blow Moulds Mold Technology

Plastics Moulding Methods Blow Moulding Rutland Plastics

Knightsbridge Plastics Inc. Plastic Molding Manufacturers

.jpg#keepProtocol)

Technical Article on Glass Moulds within the Glass Packaging Production

BLOW MOLD Hassco

Mild Steel Container Blow Mould at Best Price in Mumbai Supreme

PET Linear Stretching Blow Molding Machine with 4 Cavities,Fully

Blow Molding Process Overview North American Plastics, Ltd.

Flexcraft Custom Blow Molding & Injection MoldingMold Design & Mfg

Still the best blow mold haul I’ve ever had. Hoping to add the

Vintage Pumpkin Blow Mold Candy Container Jack-o-Lantern Trick or Treat 1980 Carolina Enterprises Inc. (194) Sale Price $23.20 $ 23.20 $ 29.00 Original Price $29.00 (20% off) Sale ends in 13 hours Add to Favorites Vintage 1980 Carolina Enterprises Pumpkin Blow Mold Candy Pail Bucket Halloween Basket Bowl 6.5″ Without Handle**Read.. The words that set “injection blow molding” and “extrusion blow molding” apart are the words “through a die”, and “into a mold”. Let me explain: Extrusion blow molding squeezes the plastic through a die to make a blow molded part; whereas, Injection blow molding pushes the plastic into a mold, then ejecting the part and inflates it with air once cooled off.